Acetate vs. Injection Glasses: Which Material Is Right for Your Eyewear Line

October 20, 2025

Acetate vs. Injection Glasses: Which Material Is Right for Your Eyewear Line?

Many newcomers to the eyewear industry — and even some experienced buyers — often struggle to tell the difference between acetate and injection-molded frames. At first glance, both can look quite similar, but the materials, production methods, and visual effects are very different.

In this article, we’ll take a closer look at how these two materials are made, how to distinguish them, and how to choose the right one for your next eyewear collection.

1. Understanding Acetate: The Craftsmanship Behind the Shine

Acetate, also known as cellulose acetate, is a high-quality, plant-based material derived from cotton or wood pulp. It has long been the preferred choice for premium eyewear thanks to its natural luster, smooth texture, and deep color richness — qualities that are hard to replicate with injection plastic.

What makes acetate special is not just its look, but how it’s made. Each acetate frame is cut and shaped from solid sheets, then polished for hours (sometimes even days) to achieve that signature glossy finish. This natural shine isn’t painted or sprayed on — it's born from meticulous craftsmanship.

Another feature that distinguishes acetate frames is the laminated nose pad construction. The nose pad section is usually attached using transparent acetate sheets, which gives a clean, almost invisible finish. This is something you can immediately recognize — in contrast, most injection frames have nose pads molded directly as part of the frame, and thus they share the same color as the front.

So, if you see transparent nose pads on an otherwise colorful frame, chances are you're looking at an acetate piece.

2. The Science of Color: Depth vs. Surface

Acetate frames are known for their color depth and material integrity. The patterns and hues are built into the sheet itself, not applied afterward. That means if you cut an acetate frame in half, you’ll find the same pattern and color running all the way through.

Injection frames, on the other hand, get their colors differently. For solid tones, pigments can be mixed directly into the plastic before molding, resulting in even color distribution. However, for patterned designs — such as tortoiseshell or gradient finishes — the effect is usually achieved through surface processes like painting or heat transfer printing.

This means that while injection frames can mimic the look of acetate, the pattern only exists on the surface. Once scratched or worn, the underlying color may appear different — something that never happens with genuine acetate.

3. Injection-Molded Frames: Precision and Efficiency

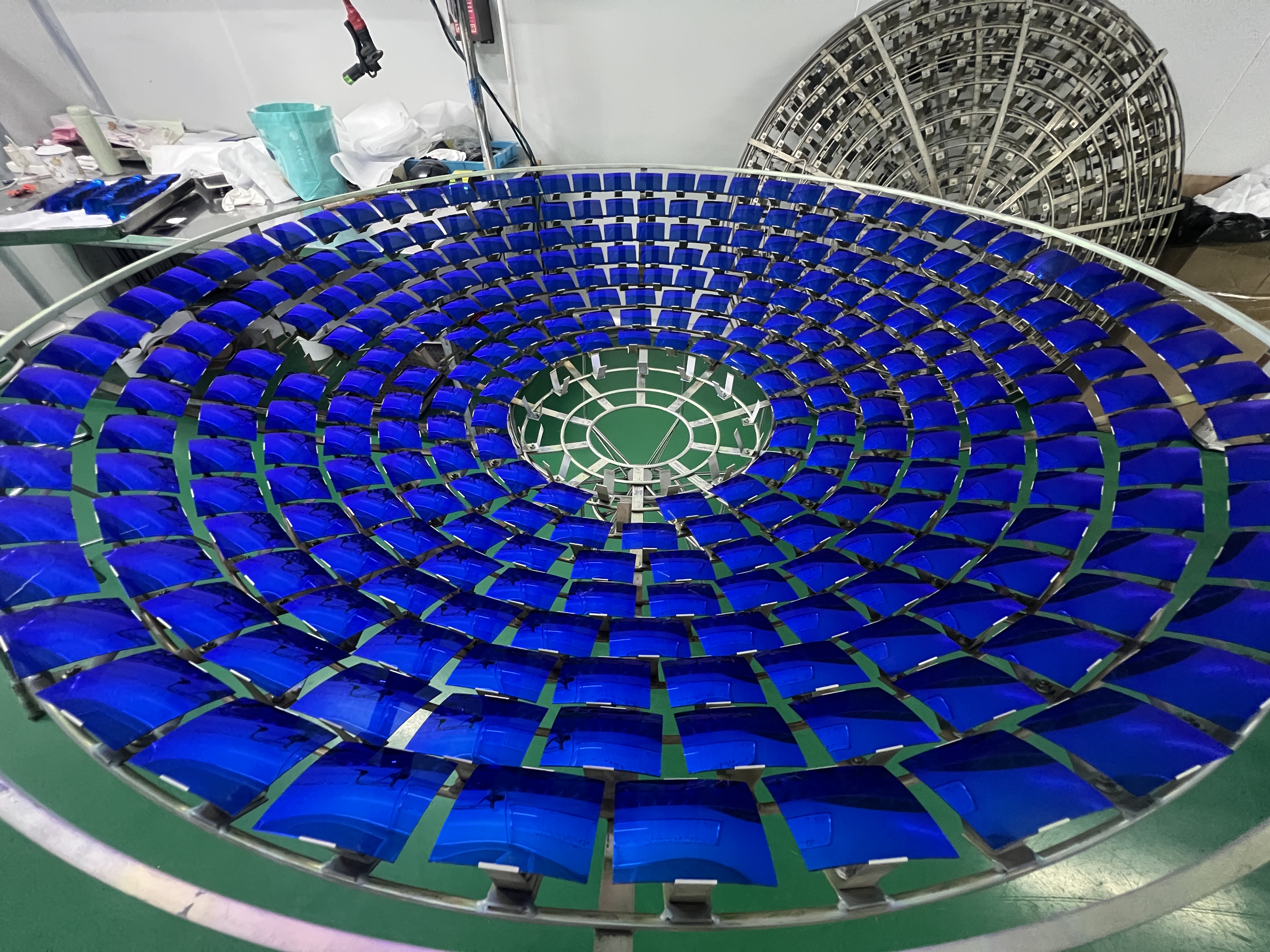

Injection frames are produced by melting plastic pellets (such as TR90 or nylon-based materials) and injecting them into a mold. This method is highly efficient and consistent, allowing for large-scale production with minimal variation.

Unlike acetate, which is limited by sheet thickness and must be shaped manually, injection molding allows for complex 3D designs, thinner profiles, and integrated structures. That’s why many sport, performance, and kids' eyewear lines use injection materials — they’re lightweight, durable, and can achieve shapes that acetate simply cannot.

However, the surface gloss of injection frames often comes from paint or coating, not from the base material itself. This can make them look slightly different — less “organic,” but often sleeker or more technical, depending on the finish.

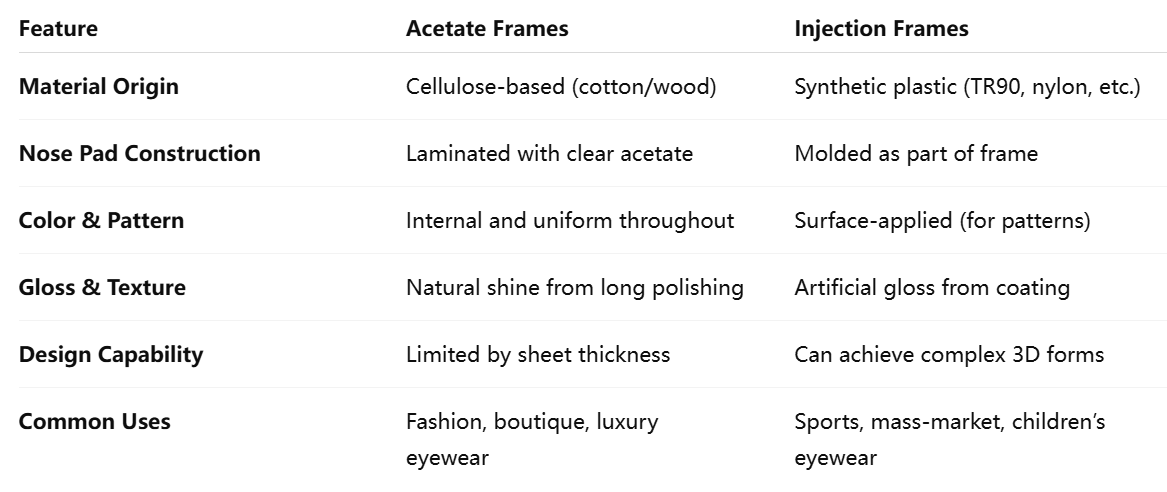

4. Quick Guide: How to Tell the Difference

5. Choosing the Right Material for Your Eyewear Line

Ultimately, the decision between acetate and injection depends on your brand identity and target audience:

-

Choose acetate if your brand values craftsmanship, texture, and long-lasting visual appeal. Perfect for designer labels or boutique eyewear lines.

-

Choose injection if your brand focuses on efficiency, large-scale production, or performance-oriented collections. Great for sports, kids, and budget-friendly ranges.

Many brands also experiment with hybrid designs — for example, acetate fronts paired with injection temples — balancing premium aesthetics with practical flexibility.

6. Bright Eyewear’s Professional Insight

At Bright Eyewear, we’ve worked with global eyewear brands across luxury and mass-market segments. Our technical team helps clients understand how materials affect not just the look, but also the feel, durability, and market perception of each collection.

Whether you’re launching a handcrafted acetate line or an innovative injection series, we can guide you through design, prototyping, and production — ensuring your products align with your vision and the market trends of the upcoming seasons.

👉 Explore our manufacturing services here or contact us for a quote.