Eyewear Hinge Screws Explained: A Practical Guide Every Brand Should Know

January 13, 2026

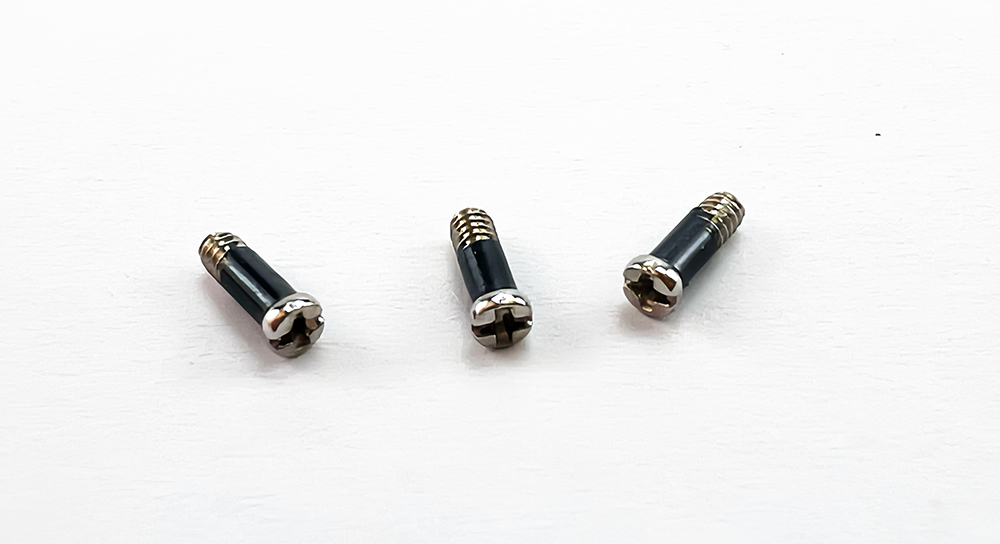

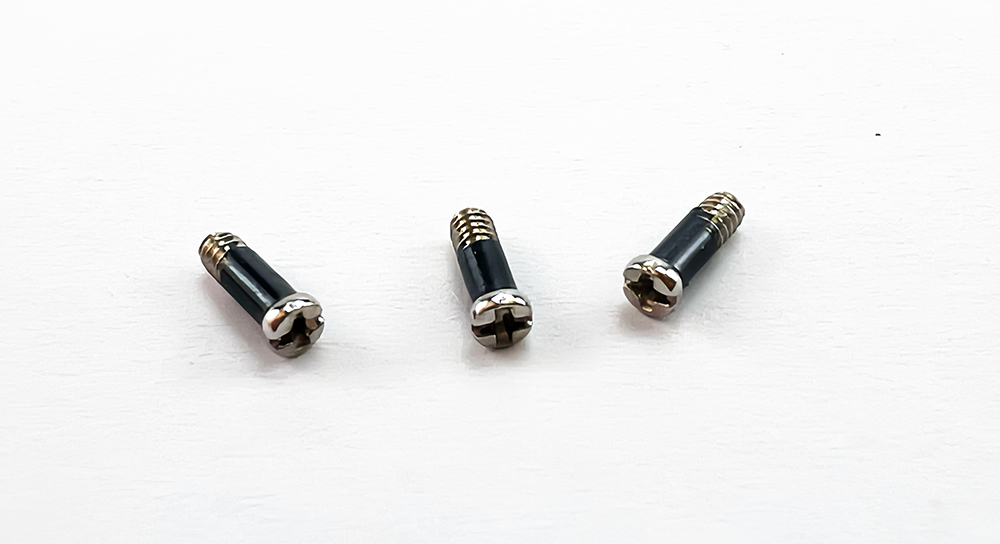

If there is one tiny component that causes outsized problems in eyewear, it's the hinge screw.

Loose temples, arms that won't stay open, customer complaints after only a few weeks of wear — very often, the root cause is not the hinge itself, but the screw inside it. Yet many eyewear brands and wholesalers simply call it "the screw" and stop there.

In reality, hinge screws come in different shapes, slots, and anti-loosening solutions. Understanding these differences makes it much easier to diagnose quality issues, communicate clearly with suppliers, and choose the right specification from the start.

Let's break it down — no engineering degree required.

1. Classification by Screw Head Shape

Round Head Screws

Round head screws are the most commonly used hinge screws in eyewear.

Characteristics:

-

The head sits slightly above the hinge surface

-

Easy to install and remove

-

Tolerates minor misalignment better than flat head screws

Typical use:

-

Standard metal frames

-

Acetate frames with metal core hinges

-

High-volume production models

Common issues:

If the screw loosens over time, it’s usually not the head shape’s fault — it’s more likely related to thread fit or missing anti-loosening treatment.

Flat Head Screws

Flat head screws are designed to sit flush with the hinge surface.

Characteristics:

-

Cleaner appearance

-

Requires precise hinge countersinking

-

Less forgiving during assembly

Typical use:

-

Higher-end frames

-

Designs where aesthetics matter more

-

Slim or minimalist hinges

Common issues:

If the countersink angle doesn’t perfectly match the screw head, stress concentrates at the hinge and loosening or deformation can occur.

2. Classification by Slot Type (How the Screw Is Driven)

Slotted (Flat / One-Line) Screws

This is the “classic” screw style — one straight line.

Pros:

-

Simple tooling

-

Traditional look

-

Easy to source

Cons:

-

Slips easily during tightening

-

Lower torque control

-

More prone to damaging the screw head

Best for:

-

Repair-friendly designs

-

Low-torque hinge applications

Phillips (Cross) Screws

The most widely used option in modern eyewear manufacturing.

Pros:

-

Better torque control

-

Less slipping during assembly

-

Faster installation in production lines

Cons:

-

Still not immune to loosening if thread fit is poor

Best for:

-

Mass production

-

Automated or semi-automated assembly

-

Most modern metal hinges

Anti-Slip / Special Drive Screws

Some screws feature modified slots designed to reduce cam-out (tool slipping).

Pros:

-

Better torque transfer

-

Reduced assembly damage

-

More consistent tightening

Cons:

-

Requires matching tools

-

Slightly higher cost

Best for:

-

Premium frames

-

Brands focused on long-term durability

3. Anti-Loosening Solutions (Where Most Problems Are Actually Solved)

This is the section most brands overlook — and where most hinge complaints originate.

Coated Screws (Sleeved Screws)

Also known as plastic-coated or sleeved screws.

How they work:

A thin layer of coating is applied to the screw shaft, increasing friction once installed in the hinge.

Benefits:

-

Excellent resistance to loosening

-

No extra assembly steps

-

Consistent performance in mass production

Common misunderstanding:

Some brands think the coating is "decorative" . It's not — it's functional.

Thread-Locked Screws (Glue-Applied Screws)

These screws have an adhesive coating on the threaded portion, which increases the friction between the hinge and the screw.

Benefits:

-

Strong resistance to vibration loosening

-

Widely used in premium frames

4. Additional Practical Classifications (Often Missed)

Screw Length & Diameter

Even a 0.2 mm difference matters.

-

Too long → hinge binding or arm stiffness

-

Too short → insufficient thread engagement → loosening

Always confirm:

-

Thread diameter

-

Thread pitch

-

Total length

-

Effective thread length

Material Type

-

Stainless steel (most common)

-

Nickel silver

-

Brass (less common today)

Material affects:

-

Corrosion resistance

-

Thread wear

-

Long-term stability

Left-Hand vs Right-Hand Threads (Rare but Real)

Used in special hinge systems to prevent self-loosening from repetitive motion.

Not common — but worth knowing when troubleshooting “mystery loosening.”

5. How This Knowledge Helps You Talk to Your Supplier

Instead of saying:

“The hinge screw keeps falling out.”

You can say:

“We’re using a round head Phillips screw, no coating, no thread lock. We need an anti-loosening solution — either coated or pre-applied adhesive — and a tighter thread tolerance.”

That one sentence saves weeks of back-and-forth.

How Bright Eyewear Approaches Hinge Screw Selection

At Bright Eyewear, hinge screws are never an afterthought. We select screw specifications based on:

-

Frame material (metal / acetate / injection)

-

Hinge design and thickness

-

Target market wear habits

-

Repair expectations

-

Production volume

We test different screw options during sampling, not after complaints appear.

Small part. Big difference.

Final Thought

A hinge screw may be tiny, but it's one of the most critical components in eyewear durability. Understanding its types, functions, and limitations gives brands better control over quality — and far fewer emails starting with “The temples are loose again.”

If you're developing new frames and want help choosing the right hinge screw system from the start, we’re happy to talk — screws included.

👉 Explore our manufacturing services here or contact us for a quote.