Eyewear Manufacturing in China: What Global Brands Need to Know

July 09, 2025

For decades, China has been the backbone of the global eyewear supply chain — and in 2025, that hasn’t changed. What has changed, however, is the level of expectation. Today’s global eyewear brands aren’t just looking for low-cost production; they want reliable partners, flexible capabilities, and a deep understanding of product design and market fit.

If you’re considering manufacturing eyewear in China — whether for a startup label or an established brand — here’s what you really need to know.

🏭 China Is No Longer Just "Cheap" — It's Specialized

The old perception that China is only good for basic, low-cost production is outdated. In fact, some of the most sophisticated eyewear craftsmanship now comes from regions like:

-

Wenzhou – Acetate & stainless steel frames with mature infrastructure

-

Dongguan/Shenzhen – Premium, tech-integrated, fashion-forward lines

-

Xiamen – Injection-molded sports and performance eyewear

At Bright Eyewear, we've seen the shift from "get it made" to “let's build it right.” It's not about mass output anymore — it's about building products that represent a brand's DNA.

🎨 Manufacturing Is About More Than Just Output — It's Collaboration

Modern eyewear manufacturing is no longer a hand-off. The best factories today work closely with clients in a creative, solution-driven partnership.

Even if you're not a trained designer, we can help. Many clients just send us reference frames, rough sketches, or even moodboards — and we help turn those loose ideas into technical drawings, material options, and working samples.

Whether you're clear on every millimeter or just starting with an idea, what matters is that you're involved. We’ll do the rest to bring your vision to life.

📐 Material, Craft, and Function Are Now Interconnected

Today’s frames must check multiple boxes: they need to look great, feel comfortable, be durable, and meet compliance standards across regions.

Here's a breakdown of how material choice influences design and function:

-

Acetate – Rich color layering, perfect for fashion-forward optical collections

-

Stainless Steel – Sleek and minimal, with excellent corrosion resistance

-

TR90 – Light, durable, great for youth and active categories

-

Titanium – Premium, ultra-lightweight, often used in executive or Japanese-style frames

-

TAC lenses – Excellent for polarized sports sunglasses

-

Nylon lenses – Ideal for frameless or drilled lenses due to high flexibility

Our role isn’t just to provide materials — it's to match the right materials with the right purpose, always aligned with your market and product goals.

📦 Production Is Only Part of the Picture — Logistics, QC, and Branding Matter Too

In today's market, eyewear buyers want more than just a frame. They want a finished product — with brand identity, quality integrity, and hassle-free logistics built in.

That’s why Chinese eyewear manufacturers are evolving beyond production. More and more suppliers are offering integrated, “one-stop” services that cover:

-

Logo engraving or printing

-

Custom packaging (boxes, cloths, cases, tags)

-

Drop test, nickel release, CE/FDA-level quality control

-

Shipping consolidation and export documents

-

Visual content support for online sales or crowdfunding

This full-package approach saves clients time, reduces communication errors, and makes the entire experience faster and more manageable — especially for small to mid-sized brands that don’t have teams in Asia.

Bright Eyewear has had exactly this kind of cross-functional workflow, so clients can go from idea to shelf-ready product without juggling five vendors and three time zones.

🤝 What Brands Should Look for in a Chinese Manufacturer

Choosing the right manufacturing partner is one of the most strategic decisions a brand can make — especially when you're working across borders, cultures, and time zones.

Look for:

-

Responsiveness: You need timely answers to keep your project moving

-

Transparency: A professional partner should tell you what's possible and what isn't — with clarity

-

Technical depth: Understanding structure, materials, and compliance isn’t optional

-

Long-term mindset: The best suppliers don't just deliver — they think ahead with you

-

Professional integrity: A supplier who takes ownership of quality, deadlines, and communication is invaluable

These qualities are what separate a transactional vendor from a true production partner. And that difference can shape the success — or failure — of your product line.

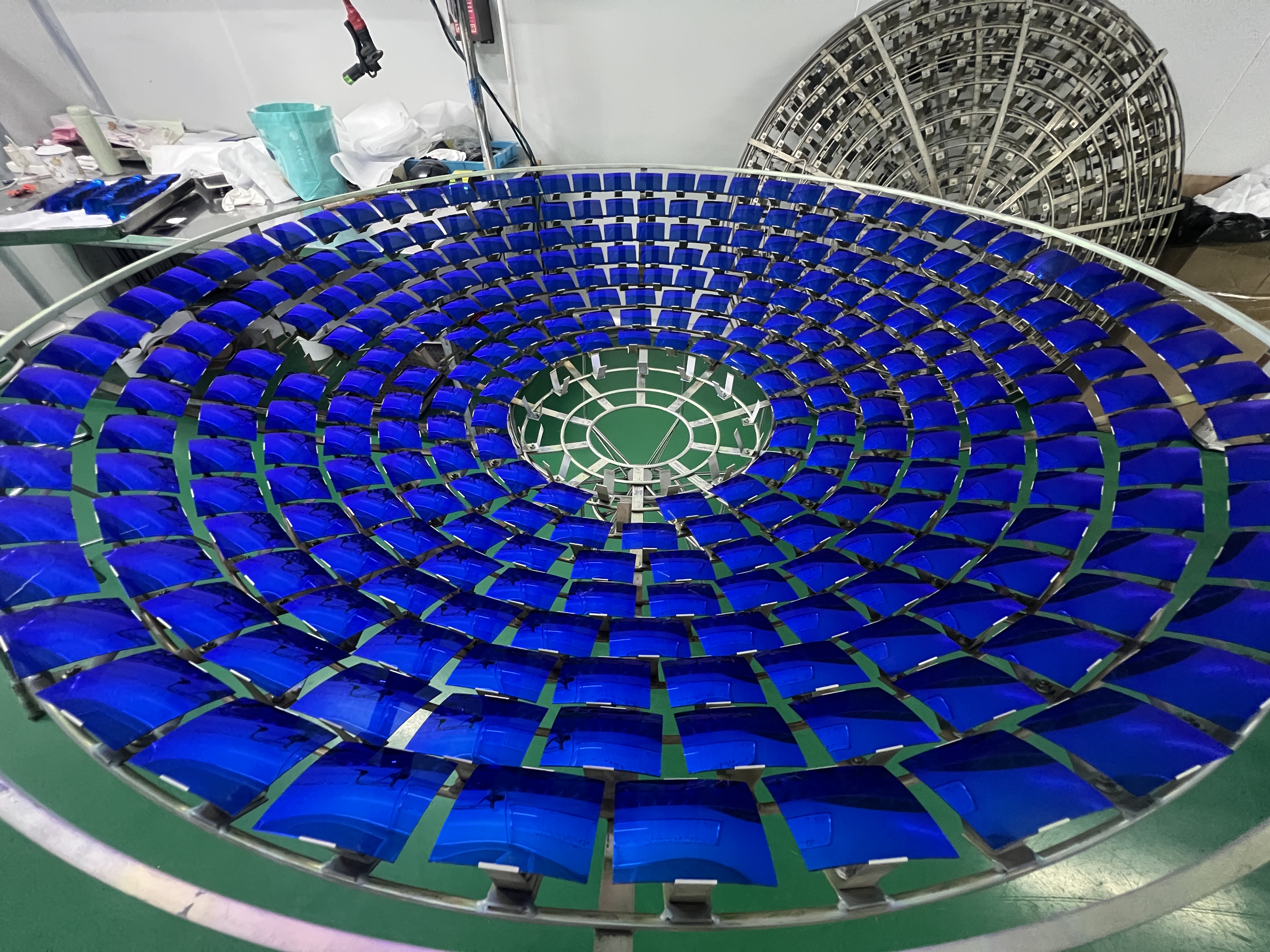

🎥 Want to See It Firsthand? Watch Behind the Frame

We believe transparency builds trust. That's why we launched Behind the Frame, a video series documenting real eyewear production — from acetate cutting to hinge installation, lens assembly, and final QC. No filters. No factory animations. Just real work by real people.

📩 Let's Talk

If you're planning to manufacture eyewear in China — or frustrated with your current supplier — let's have a conversation. We're happy to share insights, suggest a prototype plan, or discuss how we can improve your next product cycle.